Motor Assembly/Disassembly Instructions – 3" Dynabuffer

(continued)

8. Use the larger end of the 57091 Bearing Press Tool to press the 57088 Bearing down to the top of the counter weight of the 57422 Motor Shaft Balancer. Also install the

51366 Bearing Plate in the same manner.

9. Install the 56047 Key into the 57422 Motor Shaft Balancer.

10. Install the 57113 Rotor/Blade Set (5/pkg.). Apply the 95842 Dynabrade Air Lube (10W/NR or equivalent) to the vanes.

11. Position the 58358 Cylinder Assembly so that the short line-up pin side fits against the 51366 Bearing Plate.

12. Install the 51367 Bearing Plate and the 01206 Bearing onto the 57422 Motor Shaft Balancer. Note: The 01206 Bearing is a slip fit into the 51367 Bearing Plate. Use the

smaller end of the 57091 Bearing Press Tool to press the bearing/plate down only until the 51367 Bearing Plate comes in contact with the 58358 Cylinder Assembly. This

should create a snug fit between the bearing plates and the cylinder.

13. Install the 95626 Retaining Ring with retaining ring pliers so that the curve of the ring is arched up. Press the ring down into the groove at the top of the motor shaft balancer.

14. Install the 59058 Lock Ring with the 50659 O-Ring over the counter balance of the motor shaft balancer so that the o-ring fits against the 51366 Bearing Plate. Apply a

small amount of the Loctite #567 (or equivalent) to the threads of the lock ring.

15. Apply the 95842 Dynabrade Air Lube (10W/NR or equivalent) to the 58357 Cylinder Seal and install it into the side of the cylinder.

16. Carefully install the motor assembly into the 02099 Housing so that the 98462 Pin fits into the line-up hole on the inside of the housing. Note: Grasp the motor assembly

by the counter balance while applying pressure against the 59058 Lock Ring with the tips of your thumb and index finger. Align the 98462 Pin with the hole on the inside of

the 02099 housing and carefully insert the air motor into the housing until the lock ring comes in contact with the internal threads of the 02099 Housing. Using your finger

tips, turn the lock ring clockwise into the housing. If resistance is felt, stop and realign the motor assembly. If the motor assembly is aligned correctly the lock ring and the

motor should advance into the housing easily. Before the lock ring and motor are tightened all the way into the housing, fit the 51361 Shroud over the counter balance and

thread the shroud onto the external threads of the 02099 Housing. Use the 56058 Lock Ring Tool to thread the 59058 Lock Ring into the 02099 Housing. Use the 57092

Repair Collar to hold the 02099 Housing in a vise when securing the lock ring. (Torque to 28 N•m/250 in.- lbs.)

Motor Assembly Complete. Tool Assembly Complete.

Throttle Positioning Procedure:

1. Place the 52296 Repair Collar around the valve housing and secure it in a vise so that the 02099 Housing is pointing up.

2. Slip the 01547 Collar down onto the valve housing to expose the 01461 Lock Nut.

3. With a firm hold on the 02099 Housing, use a 34mm or an adjustable wrench to turn the 01461 Lock Nut counterclockwise to loosen the 02099 Housing from the valve housing.

4. Orient the throttle lever to the operators desired grip and positioning. Note: Allow for additional rotation of the 02099 Housing as the 01461 Lock Nut is tightened.

5. With a firm hold on the 02099 Housing to reduce its rotation, use a 34mm or an adjustable wrench to tighten the 01461 Lock Nut. (Torque to 45 N•m/400 in.- lbs.)

Important: Carefully perform this procedure so as not to entirely separate the 02099 Housing from the valve housing. Loosen the 01461 Lock Nut only enough to

make the desired throttle lever adjustment.

Note: Motor should operate at between 9,000 and 11,000 RPM free speed with 80 PSIG of air at the inlet of the tool. RPM should be checked with a tachometer. Before

operating, we recommend that 2-3 drops of Dynabrade Air Lube P/N 95842 (or equivalent be placed directly into the air inlet with throttle lever depressed. Operate the machine

for approximately 30 seconds before application to workpiece to determine if machine is working properly and safely and to allow lubricating oils to properly dispense

through machine. Loctite

®

is a registered trademark of the Loctite Corp.

Disc pad Change:

1. Insert 50679 Wrench on flats of 57069 Balancer Shaft and twist off sanding pad by hand.

2. With wrench still in place, hand tighten new pad on tool.

3. No need to remove shroud.

Model Motor Motor Sound Maximum Air Flow Air Pressure Spindle Weight Length Height

Number HP (W) RPM Level CFM/SCFM (LPM) PSIG (Bars) Thread Pound (kg) Inch (mm) Inch (mm)

57126 .16 (119) 10,000 74 dB(A) 3/23 (651) 80 (5.5) 5/16"-24 female 2.0 (.91) 8-5/16 (211) 3-3/4 (96)

Additional Specifications: Air Inlet Thread 1/4" NPT • Hose I.D. Size 3/8" (10mm) • Tool Vibration Data (Per ISO 8662.8) 2.0

M

/

S

2

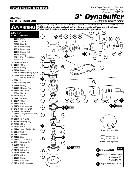

Optional Accessories

DYNABRADE, INC., 8989 Sheridan Drive • Clarence, NY 14031-1490 • Phone: (716) 631-0100 • Fax: 716-631-2073 • International Fax: 716-631-2524

DYNABRADE EUROPE S.àr.l., Zone Artisanale • L-5485 Wormeldange—Haut, Luxembourg • Telephone: 352 76 84 94 1 • Fax: 352 76 84 95 1

©DYNABRADE, INC., 2004 PRINTED IN USA PD03.10_Rev.1_02/04

Visit Our Web Site: www.dynabrade.com Email: Customer.Service@Dynabrade.com

96537 Motor Tune-Up Kit

•

Includes assorted parts to

help maintain and repair motor.

53163 Handle

•

Handle is designed for

two-handed operation.

53209 Ergo-Handle

•

This anti-vibration handle

provides increased comfort

for the operator.

52296 Repair Collar

• Specially designed collar for use in vise to

prevent damage to valve body during

disassembly/assembly.

57092 Repair Collar

• Specially designed collar for use in vise to

prevent damage to motor housing during

disassembly/assembly.

57091 Bearing Press Tool

• Use with a #2 arbor press to achieve

accuratepress of bearings and motor parts.

96525 Tool Repair Kit

• Includes special tools for proper

disassembly/assembly of the tool.

• Includes all above listed tools.

56058 Lock Ring Wrench

• Lock Ring Tool has a 3/8 in. square socket

for use with 3/8 in. drive; breaker bar,

ratchet head, or torque wrenches.

80030 Training and Maintenance Test Equipment Kit:

• 80025 Load Cell measures tool RPM under load and useful for training operators

for proper buffing pressure/operation. Electronic tachometer pick-up securely

fastens to wear plate.

• 94315 Pressure Gage to ensure peak operating performance.

• 95842Air Lube formulated for pneumatic tools. Prevents rust and formation of

gum/sludge for longer tool operation with greater power and less downtime.

• 96368Tachometer used to measure tool RPM.

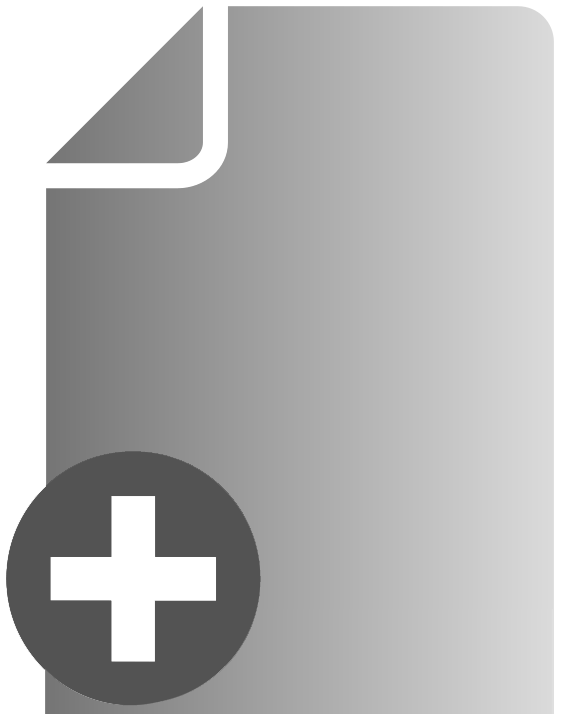

Filter-Regulator-Lubricator

11405: 40 SCFM @ 100 PSIG, 3/8" NPT female ports.

• Provides accurate air pressure regulation, two stage

filtration of water/contaminants and lubrication of

pneumatic components.