9 10

3M™DieGrinderaccessoriesaredesignedforuseon3MDieGrinders.

Constructedfrompremium,industrial-qualitymaterials,theirdurabilityand

preciseconstructionaretheidealcomplementtotheperformanceofthe3M

DieGrinder.SeeProductConguration/Specicationstableforthecorrect

replacementpadforaparticularmodel.

See3MASDAccessorycatalog61-5002-8098-9and61-5002-8097-1for

additionalAccessories.

Removingandremountingshanksandshaft

mountedabrasiveproductsintocolletchuck

1. Disconnectairlinefromtool.

2. Removecurrentlymountedshaftaccessory,shankorabrasiveproduct

fromcolletchuck*byusingthetwowrenchessuppliedwiththetool.Use

thewrenchtosecurethecolletbodywhileturningthecolletnutcounter

clockwise.

3. Aftertheexistingproducthasbeenremovedfromthecollet,inspectthe

colletinserttoensurethatisfreeofdebrisandundamaged.

4. Fullyinsertthenewshaftmountedaccessory,shankorabrasiveproduct

intothecollet.

5. Securethecolletbodywiththewrenchandtightenthecolletnut

securely.Alwaysusethecorrectsizedcolletwiththematchingshank

(use1/4incolletinsertwith1/4inshaftsor6mmcolletinsertwith

6mmshafts).Aninadequatelyinsertedshankcouldbendorbreak

causingdamagetothetoolandworkpieceandpossibleinjurytothe

operatororbystanders.

Note:Duringtheabovesteps,ensurethatallhardwareandabrasive

productsaremountedconcentricallyonthesupportingaccessory.

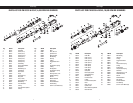

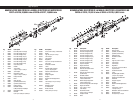

*InthedrawingsonthePartsPages,Figures1,2and3comprisetheCollet

Chuck.

1. Readallinstructionsbeforeusingthistool.Alloperatorsmustbefully

trainedinitsuseandawareofthesesafetyrules.

2. ThetoolRPMshouldbecheckedonaregularbasistoensureproper

operatingspeed.

3. Makesurethetoolisdisconnectedfromtheairsupply.Selectasuitable

abrasiveandsecureittothediscpadorspindle.Becarefultocenterthe

abrasiveonthediscpad.

4. Alwayswearrequiredsafetyequipmentwhenusingthistool.

5. Alwaysremovetheairsupplytothesanderbeforetting,adjustingor

removingtheabrasiveordiscpad.

6. Alwaysadoptarmfootingandgripandbeawareoftorquereaction

developedbythesander.

7. Useonly3Mapprovedspareparts.

8. Alwaysensurethematerialbeingworkedisrmlyxedtoavoid

movement.

9. Checkhoseandttingsregularlyforwear.Donotcarrythetoolbyits

hose;alwaysbecarefultopreventthetoolfrombeingstartedwhen

carryingthetoolwiththeairsupplyconnected.

10.Dustcanbehighlycombustible.

11.IftoolisservicedorrebuiltchecktoensurethatthemaximumtoolRPM

isnotexceededandthatthereisnoexcessivetoolvibration.

12.Donotexceedmaximumrecommendedairpressure.Usesafety

equipmentasrecommended.

13.Priortoinstallinganyshaftmountedabrasiveorsandingorgrinding

accessory,alwayscheckthatitsmarkedmaximumoperatingspeedis

equalorhigherthantheratedspeedofthistool.

14.Thetoolisnotelectricallyinsulated.Donotusewherethereisa

possibilityofcontactwithliveelectricity,gaspipes,and/orwaterpipes.

15.Thistoolisnotprotectedagainsthazardsinherentincuttingoperations,

andnosuchcuttingproductsshouldeverbeattached.

16.Takecaretoavoidentanglementwiththemovingpartsofthetoolwith

clothing,ties,hair,cleaningragsorloosehangingobjects.Ifentangled,

stopairsupplyimmediatelytoavoidcontactwithmovingtoolparts.

17.Keephandsclearofthespinningpadorspindleduringuse.

18.Ifthetoolappearstomalfunction,removefromuseimmediatelyand

arrangeforserviceandrepair.

19.Donotallowthetooltofreespinwithouttakingprecautionstoprotect

anypersonsorobjectsfromthelossoftheabrasiveorpadruptures.

20.Immediatelyreleasethestarthandleintheeventofanydisruption

ofpressure;donotattempttore-startuntilthedisruptionhasbeen

corrected.

21.Whentoolisnotinuse,storeinaclean,dryenvironmentfreeofdebris.

22.RecycleordisposeoftoolaccordingtoLocal,State,andFederal

regulations.

SafetyPrecautions

3M™DieGrinder

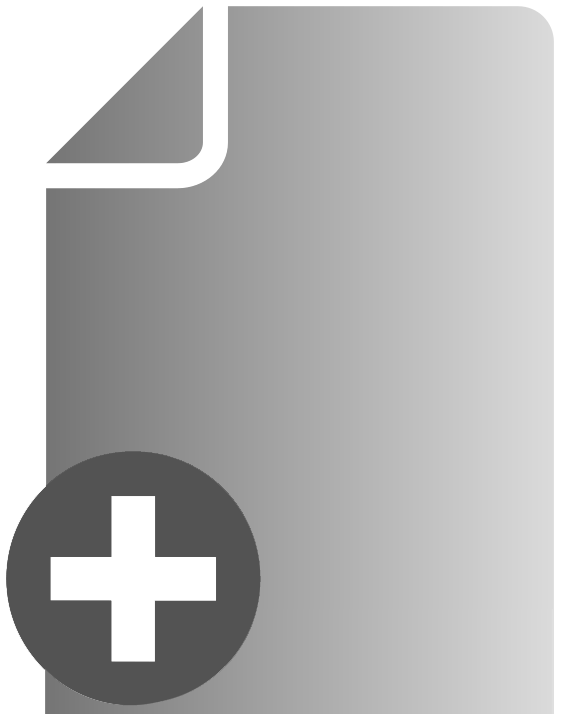

Figure1

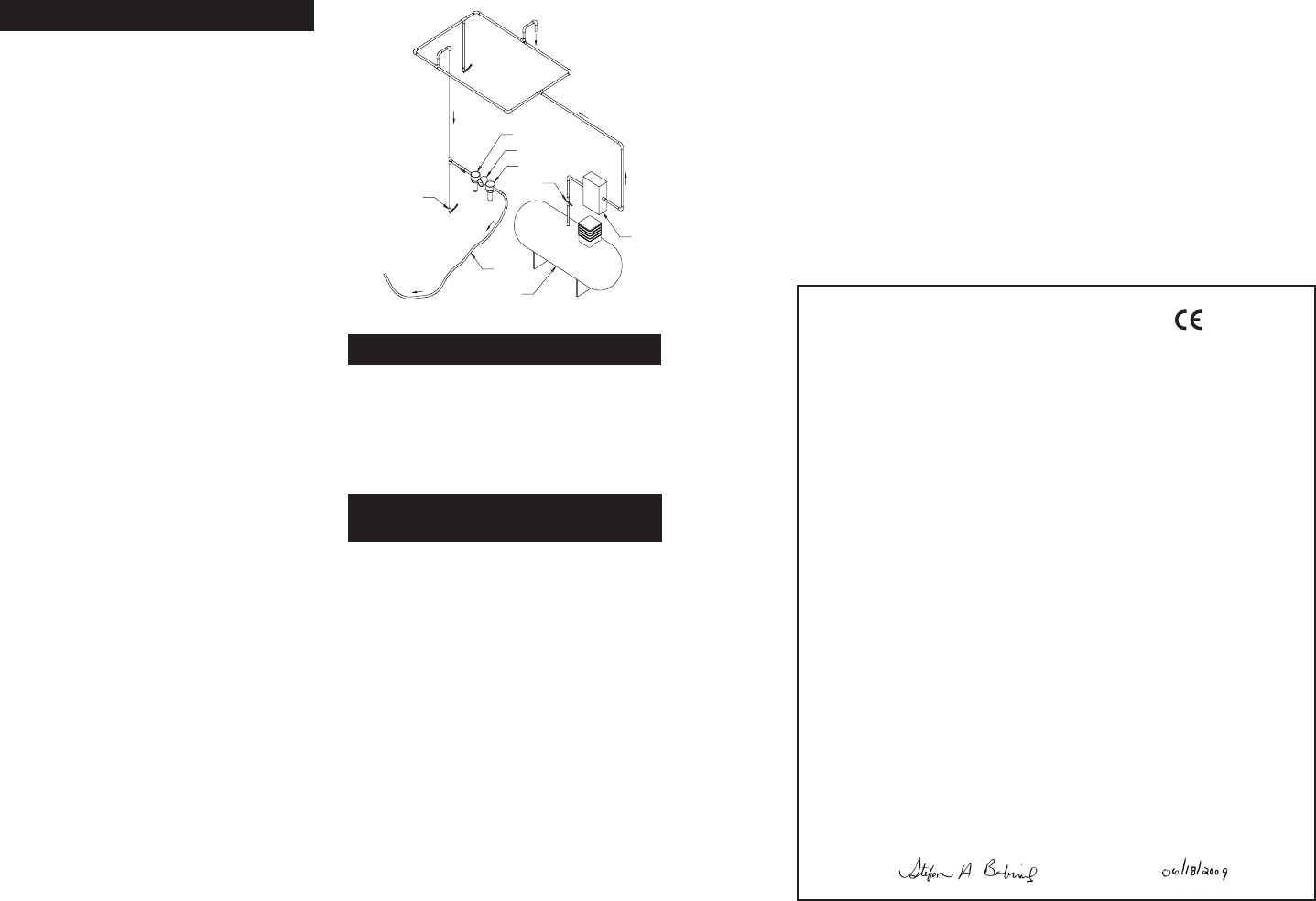

Closed Loop Pipe System

Sloped in the direction of air flow

Drain Leg

Ball Valve

To Tool Station

Filter

Drain Valve

Regulator

Lubricator

Ball

Valve

Ball Valve

Air Flow

Air Dryer

Air Compressor

and Tank

Air Hose

To Coupler

at or near Tool

Product Use: Allstatements,technicalinformationandrecommendations

containedinthisdocumentarebasedupontestsorexperiencethat3M

believesarereliable.However,manyfactorsbeyond3M’scontrolcan

affecttheuseandperformanceofa3Mproductinaparticularapplication,

includingtheconditionsunderwhichthe3Mproductisusedandthetime

andenvironmentalconditionsinwhichtheproductisexpectedtoperform.

Sincethesefactorsareuniquelywithintheuser’sknowledgeandcontrol,it

isessentialthattheuserevaluatethe3Mproducttodeterminewhetheritis

tforaparticularpurposeandsuitablefortheuser’smethodofapplication.

Warranty and Limited Remedy:3Mwarrantsthistoolagainstdefects

inworkmanshipandmaterialsundernormaloperatingconditionsforone

(1)yearfromthedateofpurchase.3MMAKESNOOTHERWARRANTIES,

EXPRESSORIMPLIED,INCLUDING,BUTNOTLIMITEDTO,ANYIMPLIED

WARRANTYOFMERCHANTABILITYORFITNESSFORAPARTICULAR

PURPOSEORANYIMPLIEDWARRANTYARISINGOUTOFACOURSEOF

DEALING,CUSTOMORUSAGEOFTRADE.Userisresponsiblefordetermining

whetherthe3Mtoolistforaparticularpurposeandsuitableforuser’s

application.Usermustoperatethetoolinaccordancewithallapplicable

operatinginstructions,safetyprecautions,andotherproceduresstatedin

theoperatingmanualtobeentitledtowarrantycoverage.3Mshallhaveno

obligationtorepairorreplaceanytoolorpartthatfailsduetonormalwear,

inadequateorimpropermaintenance,inadequatecleaning,non-lubrication,

improperoperatingenvironment,improperutilities,operatorerrorormisuse,

alterationormodication,mishandling,lackofreasonablecare,orduetoany

3

Abrasive Systems Division

3MCenter,Building223-6N-02

St.Paul,MN55144-1000

www.3M.com/abrasives

©3M2009

3Misatrademarkof3MCompany

34-8703-0155-2

accidentalcause.Ifatooloranypartthereofisdefectivewithinthiswarranty

period,yourexclusiveremedyand3M’ssoleobligationwillbe,at3M’s

option,torepairorreplacethetoolorrefundthepurchaseprice.

Limitation of Liability:Exceptwhereprohibitedbylaw,3Mandsellerwill

notbeliableforanylossordamagearisingfromthe3Mproduct,whether

direct,indirect,special,incidentalorconsequential,regardlessofthelegal

theoryasserted,includingwarranty,contract,negligenceorstrictliability.

Submitting a Warranty Claim: Contactyourdealerwhensubmittinga

warrantyclaiminaccordancewiththerestrictionslistedabove.Pleasenote

thatallwarrantyclaimsaresubjecttomanufacturer’sapproval.Besureto

keepyoursalesreceiptinasafeplace.Thismustbesubmittedwhenlinga

warrantyclaim,within1yearfromthedateofpurchase.

Product Repair after Warranty Has Expired

3Mdoesnotofferrepairserviceforproductoutofwarranty.

Submitting a Warranty Claim:Contactyourdealerwhensubmittinga

warrantyclaiminaccordancewiththerestrictionslistedabove.Pleasenote

thatallwarrantyclaimsaresubjecttomanufacturer’sapproval.Besureto

keepyoursalesreceiptinasafeplace.Thismustbesubmittedwhenling

awarrantyclaim,within1yearfromthedateofpurchase.Foradditional

assistancecall1-800-362-3550.

Product Repair after Warranty Has Expired: Repairof3MAbrasivePower

toolsthatarenotunderwarrantyisavailablethrough3Mora3MAuthorized

ToolRepairRepresentative.Contactyour3MAbrasivePowerToolDistributor

fordetails,orcall1-800-362-3550.

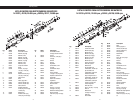

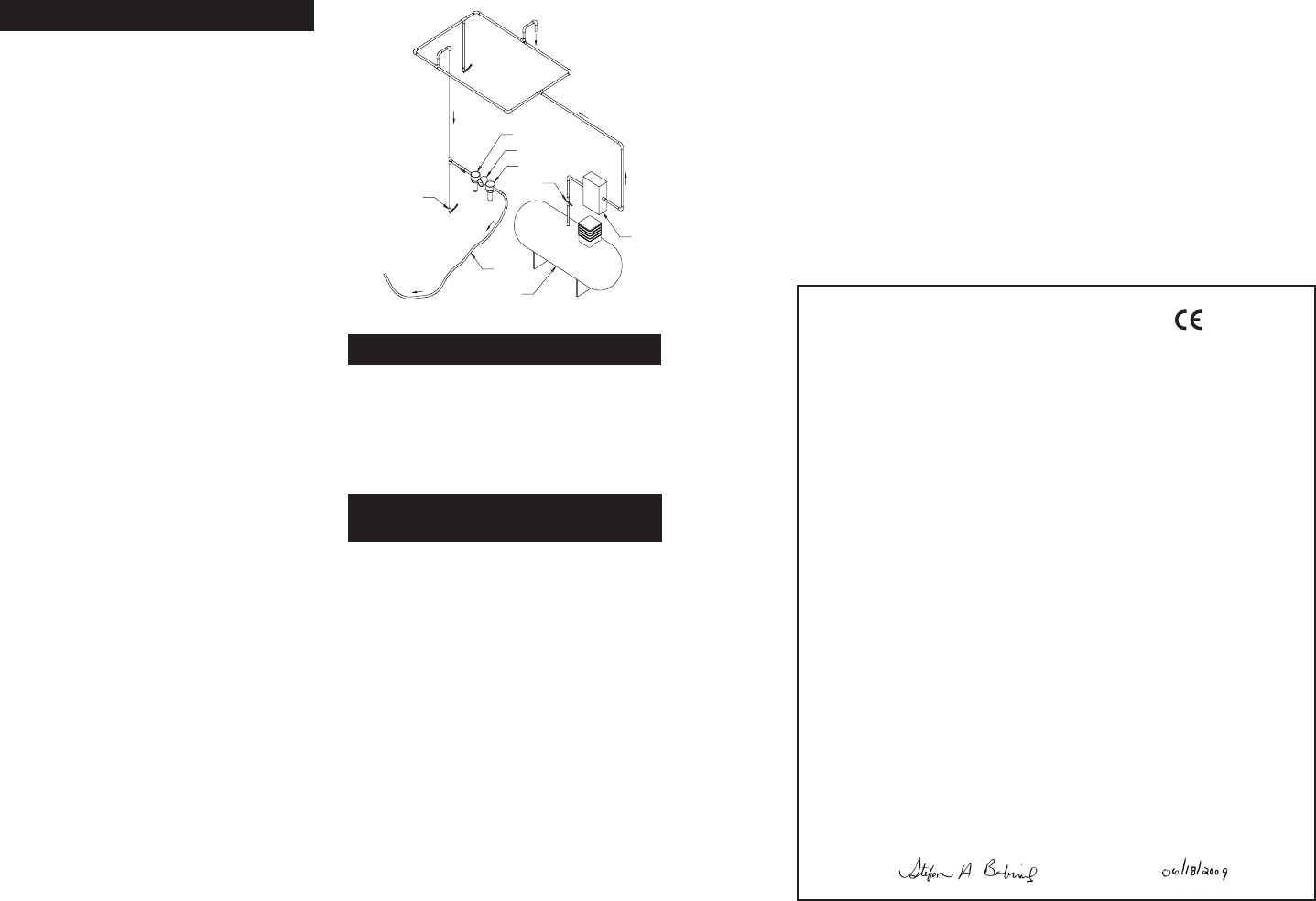

EC Declaration of Conformity

Manufacturers Name:

Manufacturers Address:

3, Abrasive Systems Division

3M Center, Building 223-6N-02

St. Paul, MN U.S.A. 55144

Does hereby declare that the machinery described below complies with those applicable essential health

and safety requirements of the Machinery Directive 98/37/EC; together with all amendments to date.

Descriptions:

Full Name of responsible person.

Stefan A. Babirad

Signature: .............................................................................

Position: Technical Director

Date: .............................................................

The following standards have either been referred to, or complied with, in full or in part as revelent:

Model Numbers: 20237, 20238, 20239, 20240, 25126, 25127, 25128, 25129, 28330, 28331, 28332, 28345, 28346,

28347

3M™ Die Grinder, 1 hp (746w), MOS 20,000 rpm, straight shaft, ¼ in collet

3M™ Die Grinder, 1 hp (746w), MOS 18,000 rpm, straight shaft, ¼ in collet

3M™ Die Grinder, 1 hp (746w), MOS 12,000 rpm, straight shaft, ¼ in collet

3M™ Die Grinder, 1 hp (746w), MOS 8,000 rpm, straight shaft, ¼ in collet

3M™ Die Grinder, 1 hp (746w), MOS 20,000 rpm, straight shaft, 6 mm collet

3M™ Die Grinder, 1 hp (746w), MOS 18,000 rpm, straight shaft, 6 mm collet

3M™ Die Grinder, 1 hp (746w), MOS 12,000 rpm, straight shaft, 6 mm collet

3M™ Die Grinder, 1 hp (746w), MOS 8,000 rpm, straight shaft, 6 mm collet

3M™ Die Grinder, 0.5 hp (373w), MOS 18,000 rpm, straight shaft, ¼ in collet

3M™ Die Grinder, 0.5 hp (373w), MOS 18,000 rpm, straight shaft, ¼ in collet-3 in extended

3M™ Die Grinder, 0.5 hp (373w), MOS 4,000 rpm, straight shaft, ¼ in collet

3M™ Die Grinder, 0.5 hp (373w), MOS 18,000 rpm, straight shaft, 6 mm collet

3M™ Die Grinder, 0.5 hp (373w), MOS 18,000 rpm, straight shaft, 6 mm collet-3 in extended

3M™ Die Grinder, 0.5 hp (373w), MOS 4,000 rpm, straight shaft, 6 mm collet

EN ISO 12100-1:2003 Safety of machinery . Basic concepts, general principles for design-

EN ISO 12100-2:2003 Basic terminology and Technical principals

EN 792-9:2001 Hand-held non-electic power tools - Safety Requirements - Part 9: Die Grinders

EN 983:1996 Safety of machinery . Safety requirements for fluid power systems and components

- Pneumatics

EN ISO 14121-1:2007 Safety of machinery . Risk assesment principles

EN ISO 28662-1:1992 Hand-held portable power tools - Measurement of vibrations at the handle

- Part 1: General

EN ISO 8662-13:1997 Hand-held portable power tools - Measurement of vibrations at the handle

- Part 13: Die Grinders

EN ISO 15744:2002 Hand-held non-electric power tools. Noise measurement code.

Engineering method (grade 2)